The Future of Engineering: Trends in Mechanical Design Courses

Introduction to Mechanical Design Courses and Their Evolution

Mechanical design courses, the backbone of engineering education, have evolved tremendously. Gone are the days of just pen and paper; now, it’s about CAD software and 3D modeling. These courses teach you how to create the machines of the future. You get to dive into robotics, learn about materials stronger than steel but lighter than air, and even explore how to make sustainable designs that Mother Nature would nod at. The game has changed, and these courses are your playbook. With each new technology, your toolkit grows, making you not just an engineer, but a shaper of the world to come. So buckle up, future designer, it’s an exciting ride ahead.

Incorporating Automation and AI in Mechanical Design Curriculum

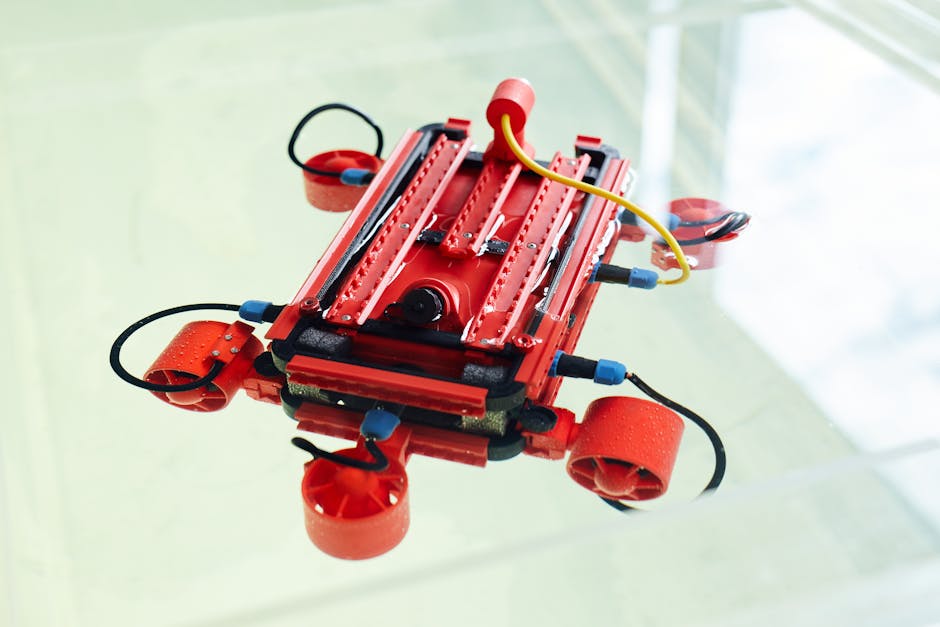

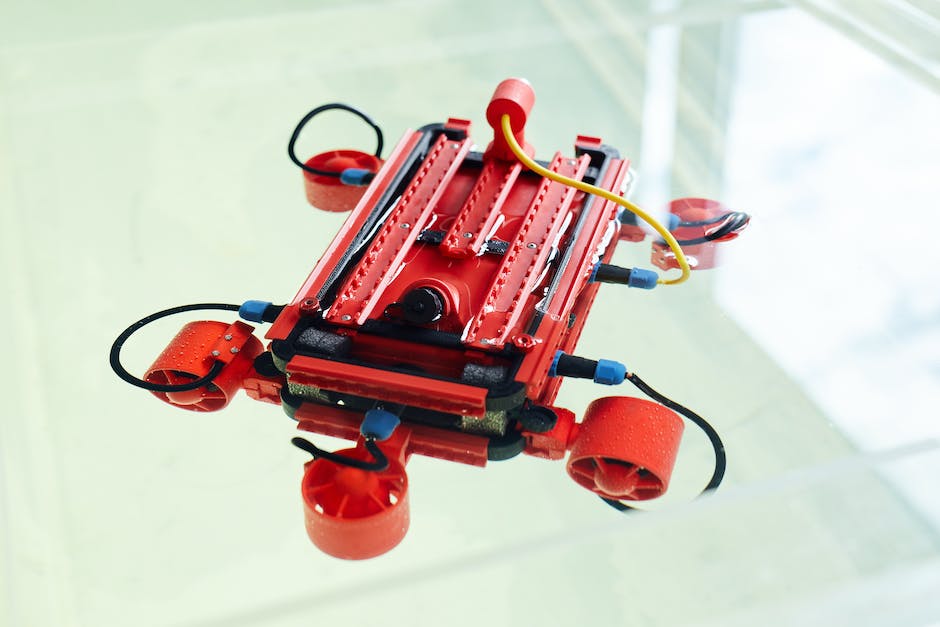

The world of mechanical design is rapidly embracing automation and artificial intelligence (AI). It means if you’re diving into this field, you’re bound to bump into these high-tech buddies. To stay ahead of the curve, mechanical design courses are now packing some serious tech into their syllabus. We’re talking about software that can think like a designer and tools that automate the grunt work. Students get to toy with AI algorithms that optimize machine parts, and they’ll learn how to let robots do the heavy lifting. The goal? To make you a design whiz who can talk to machines. It’s not about replacing human creativity but juicing it up with some AI smarts. And the best part – once you master these skills, you’ll be the hot ticket item in the engineering job market. Welcome to the future, gearheads! 🤖🛠️

The Rise of Sustainable Design Principles in Engineering Education

Sustainable design is no longer a buzzword; it’s a critical element in today’s engineering curriculum. Future engineers are learning to create tech that respects the planet. Courses now push for eco-friendly materials, energy efficiency, and designs that reduce waste. This isn’t just feel-good education; industry demand for green engineering is soaring. Companies want solutions that save resources and cut costs. As a student, you’ll dive into projects that challenge you to think about the lifecycle of your creations. You’ll measure your success not just by performance, but by your design’s environmental impact. This shift in education is shaping a new generation of engineers ready to tackle the world’s sustainability challenges head-on.

Emphasizing Software Tools: CAD, CAM, and CAE

Today’s mechanical design courses are all about giving students hands-on experience with the software tools that are shaping the future of engineering. These tools include CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and CAE (Computer-Aided Engineering). They are critical for modern mechanical engineers who must be adept at designing, analyzing, and managing the manufacturing process efficiently.

CAD is all about creating detailed 3D models. It’s not just about drawing lines; it’s about constructing a digital blueprint of what you’ll eventually hold in your hands. Mechanical design courses ensure you can navigate CAD software like a pro.

CAM software takes this a step further. It’s like an assistant that helps convert those 3D models into reality. It guides machines on how to make parts by defining the path of cutting tools. Mechanical engineers need to know CAM to bridge the gap between design and manufacturing.

Lastly, there’s CAE. This software is the behind-the-scenes hero. It allows engineers to test and simulate how a design will perform in the real world. Think of it as a virtual sandbox where engineers can see the future of a product before it’s ever made.

By emphasizing these software tools, mechanical design courses are arming engineers with the skills needed to thrive in an engineering future that’s digital, seamless, and incredibly precise.

3D Printing and Prototyping in Modern Mechanical Courses

Gone are the days when prototyping was a slog of manual adjustments and weeks of waiting. Now, 3D printing is revolutionizing how mechanical design courses operate. Students get their hands on creating real, tangible models from their CAD designs in a matter of hours. This quick turnaround isn’t just about speed; it’s a game changer for learning. By iterating rapidly, students grasp the nuts and bolts of design improvement on the fly, a skill invaluable in the real world. Plus, with a variety of materials available for 3D printing, they’re not just designing; they’re thinking about material properties, costs, and function. This technology isn’t a fancy add-on; it’s the new workshop standard, and it’s equipping future engineers with a cutting-edge skillset that employers are drooling over.

The Importance of Interdisciplinary Studies in Mechanical Design

Mechanical design isn’t just about gears and levers anymore. The field is evolving, and now it demands a mix of skills from different domains. That’s why interdisciplinary studies are crucial. They break down the old silos of learning. By blending knowledge from materials science, electronics, and even environmental science, future mechanical engineers can create more innovative and sustainable designs. Think smart cars, robots that help in disaster zones, or energy-efficient machines. These aren’t just mechanical problems; they’re complex puzzles that need a wide lens. So, for those diving into mechanical design courses, embrace the blend of math, physics, computer science, and yes, even art. Because to be at the forefront of engineering tomorrow, you’ve got to think beyond the nuts and bolts of today.

Virtual Reality (VR) and Augmented Reality (AR) in Engineering Training

Gone are the days when engineering training was confined to crowded classrooms and piles of textbooks. With Virtual Reality (VR) and Augmented Reality (AR), the game has changed. These technologies are not just buzzwords; they’re educational power tools that transport students to a new dimension of learning. Picture this: with a VR headset, a mechanical engineering student can dismantle an engine and reassemble it, piece by piece, without touching a physical bolt. And with AR, you overlay data or graphics onto the real world – think about getting real-time stats while looking at a prototype part. This high-tech training leads to better understanding, fewer mistakes, and a workforce ready for tomorrow’s challenges..isdigit(h)

The Impact of IoT and Smart Technologies on Mechanical Design

Smart technologies and the Internet of Things (IoT) are transforming mechanical design, forcing courses to adapt or fall behind. Connected devices and systems are now a core part of our environment. They talk to each other, they learn from our behaviors, and they’re getting smarter every day. In mechanical design courses, this means students must grasp how to design machines that can seamlessly integrate with these smart systems. It’s about blending traditional mechanical knowledge with cutting-edge digital design. Think smart thermostats that learn our preferred temperatures or factory machines that predict their maintenance schedule. That’s the world budding mechanical engineers are preparing for. Being at the forefront of IoT in mechanical design doesn’t just make you relevant; it puts you in demand. As these technologies advance, they’ll keep changing how we create, how we interact with machines, and how those machines interact with us. It’s an exciting shift, and it’s happening right now.

Preparing for the Industry 4.0 Revolution in Mechanical Education

As we move deeper into the fourth industrial revolution, also called Industry 4.0, mechanical engineering courses must adapt or risk becoming outdated. This period marks the blending of cyber-physical systems and the Internet of Things (IoT), transforming how we design, manufacture, and maintain mechanical systems. To ensure students are ready to hit the ground running, courses are now infusing subjects like robotics, artificial intelligence (AI), and data analytics into their curricula. This interdisciplinary approach is not just a trend; it’s a necessity. As machines get smarter, the engineers behind them must too. This means not only learning traditional mechanical design principles but also understanding how to integrate these with advanced software and analytical tools. The future promises even tighter integration between design, manufacturing, and operational processes, and education programs that embrace this will give their students a significant edge in the job market.

Conclusion: The Shifting Landscape of Mechanical Design Courses

The world of engineering constantly evolves, and so do mechanical design courses. Keeping up with the latest trends, software, and tools is no walk in the park, but it’s essential. As we wrap up, remember that the future of mechanical design is digital, collaborative, and innovative. Courses will continue to shift towards incorporating more 3D modeling, simulations, and virtual reality to prepare students for the demands of modern-day engineering. This evolution is not just a necessity but an exciting leap forward. Those who embrace these changes will find themselves at the forefront of the industry, ready to tackle the challenges of tomorrow’s engineering feats. Stay curious, stay flexible, and keep learning—that’s the engineer’s mantra in this shifting landscape.

buy cannabis nj

order thc online discreet global service