By Shivani A.

By Shivani A.

03 Nov’23 | 3 min read

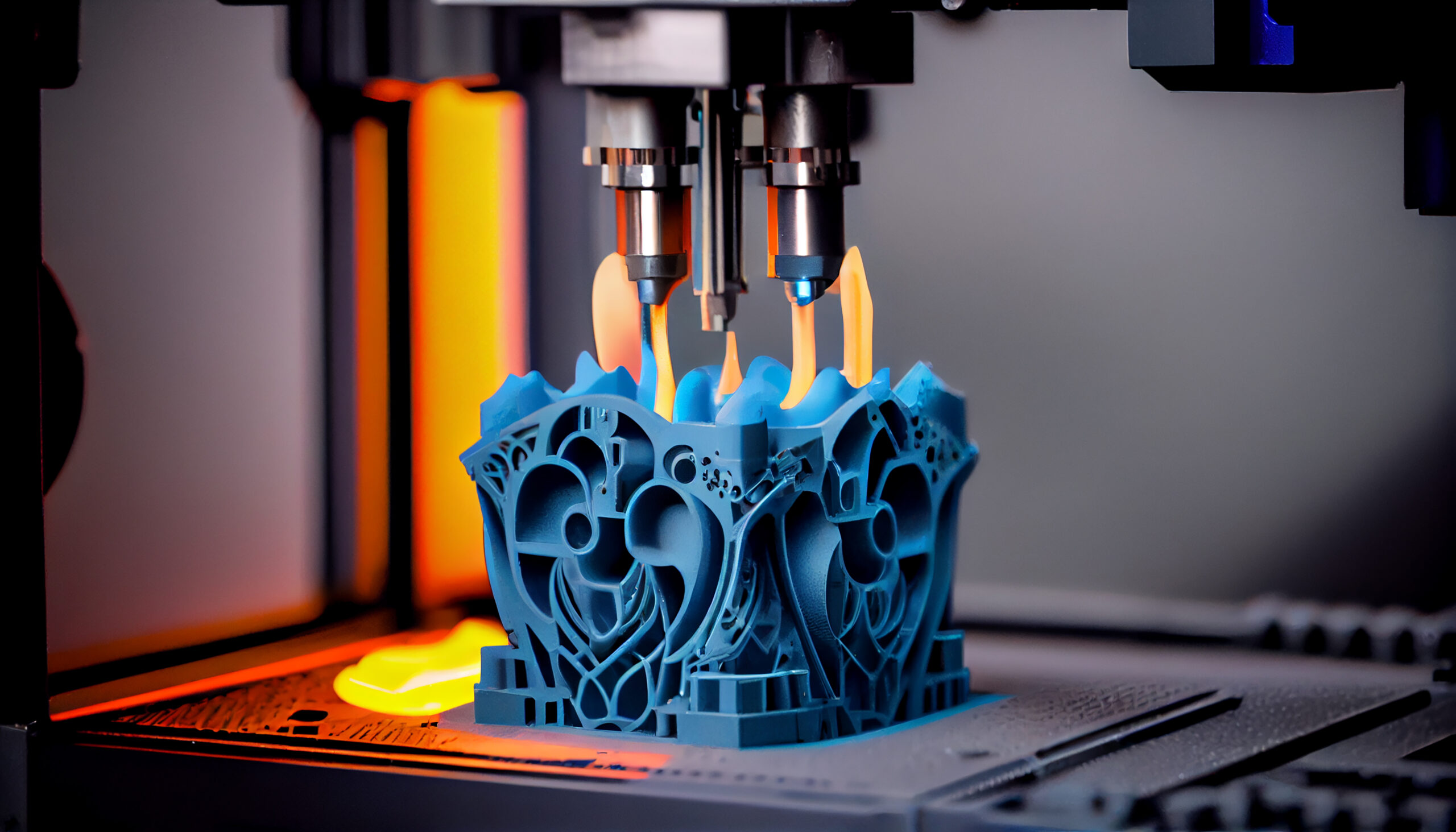

3D printing, also known as additive manufacturing, transforms design and construction practices in civil engineering. In recent years, 3D printing has expanded rapidly beyond prototyping into full-scale production across the aerospace, automotive, medical, and consumer goods sectors. Now, additive manufacturing is disrupting the civil engineering and construction industry with its unique capabilities.

Some of the key 3D printing technologies used in civil engineering applications include:

Fused Deposition Modeling (FDM): A thermoplastic filament is heated and extruded layer-by-layer based on a digital model. FDM can use materials like ABS, PLA, and engineering-grade polymers.

Stereolithography (SLA): A UV laser selectively cures photosensitive resin layer-by-layer to build the 3D object. SLA can create high-accuracy and surface finish parts using engineering resins.

Selective Laser Sintering (SLS): A laser fuses and bonds powdered material like polymers and metals to print 3D objects. SLS produces durable parts with properties comparable to molded plastics.

Binder Jetting: A liquid bonding agent is deposited to join powder layers during printing. Binder jetting enables high-resolution printing using powdered metals, sand, ceramics, and polymers.

Key Application Areas

3D printing is enabling transformative changes across major civil engineering application areas:

3D Printed Buildings: Entire buildings and houses have been 3D printed layer-by-layer using concrete extrusion methods. This allows faster, lower labor construction with material savings and architectural freedom.

Concrete Printing: 3D printing shows high potential for producing concrete components like panels, columns, slabs, and joints. It minimizes formwork and enables complex geometries.

Molds for Casting: 3D printed molds from polymers or rubber allow rapid indirect molding of precast concrete elements with intricate details and undercuts.

Reinforcement Cages: Metallic 3D printing methods are being explored for printing customized steel reinforcement cages and lattices for concrete.

Bridges: Pedestrian 3D-printed bridges have been constructed from materials like concrete, composite polymers, and stainless steel. 3D printing allowed faster assembly and unique shapes.

Dams and Hydraulic Structures: Automated layer-by-layer printing enables construction in remote locations and integration of projections and curves into dams, levees, and revetments.

Infrastructure and Components: Roads, geotechnical structures, heavy equipment parts, and other civil components are being 3D printed to leverage customization and consolidation benefits.

Recent Innovations

Ongoing 3D printing research demonstrates the vast future potential in civil engineering:

Multimaterial Printing: New multi-nozzle print systems allow the integration of different concretes and materials within a single component for functionally graded properties.

Contour Crafting Robots: Gantry-mounted robotic systems like those developed at USC aim to automate entire building construction with 3D concrete printing and finishing.

Novel Concrete Materials: Specialized concrete mixes are formulated for 3D printing with enhanced flowability, curing rates, and interlayer adhesion.

Sustainable and Local Materials: The use of recyclables, geopolymers, clay, and local site materials is being explored to improve the sustainability of 3D printed buildings and infrastructure.

Printing Software and Process Integration: Developing comprehensive software suites to integrate architectural design, structural analysis, compliance checking, print path planning, and process automation will boost adoption.

Benefits and Advantages

Key benefits 3D printing offers over conventional construction methods:

Design Freedom: Printing complex geometries not feasible with traditional techniques

Customization: Components can be tailored to unique loads and conditions with small-batch production

Reduced Labor: Automating fabrication decreases manual labor requirements

Optimized Material Use: The additive approach places material only where needed enabling lightweight designs

Faster Construction: On-site automated printing accelerates build speed up to 60% versus conventional techniques

Enhanced Performance: Organic printed shapes can improve structural performance with less material

However, challenges around costs, build size limits, weak layer bonding, and lack of codes and standards for 3D printed structures remain barriers to broader adoption. With progress in technology, materials, and processes, 3D printing is poised to realize a paradigm shift in civil engineering construction in the coming decade. Its benefits in terms of customization, speed, performance, and sustainability make it a highly compelling technology for the future of infrastructure.

Shivani A.

Mentor – Civil Engineering

SkillLiftt